Summary Points

- ISO 13485:2016 helps medical-device businesses build a strong quality management system that improves product safety and reliability.

- The certification strengthens regulatory compliance and prepares your organisation for global market entry.

- A structured QMS reduces risks, prevents errors, and enhances customer trust in your medical-device offerings.

- ISO 13485 certification boosts reputation, supports smoother audits, and creates long-term operational efficiency.

- India’s push for safe and regulated medical-device manufacturing makes ISO 13485 a strategic necessity, not just a certification.

The medical-device market is expected to reach US $586.2 billion by 2025, making quality control and proper regulatory compliance more important than ever for every business. ISO 13485 certification offers a focused Quality Management System (QMS) designed specifically for the medical-device industry.

It helps you manage risk, ensure traceability, and meet regulatory requirements effectively. At Global Quality Services, we guide companies through every stage of this journey, from initial gap assessment to post-certification support.

What is ISO 13485 Certification?

ISO 13485 is an international standard that specifies the requirements for a quality management system (QMS) dedicated to medical-device manufacturers and related organizations.

It emphasizes risk management, process validation, product traceability, and regulatory alignment across the full lifecycle design, production, installation, servicing, and disposal.

Why ISO 13485 Certification is Critical for Your Business?

ISO 13485 certification strengthens quality, reduces risks, and enhances market trust, making it a crucial investment for long-term success in the medical-device industry.

- Regulatory Readiness: Many regulatory bodies recognize or align with ISO 13485, making it a powerful asset when seeking market approvals.

- Risk Control: By embedding systematic risk management, the standard reduces the likelihood of device failures, recalls, or safety issues.

- Global Market Access: Certification improves your credibility and opens doors to international markets where compliance is a must.

- Operational Efficiency: A structured QMS helps eliminate redundancies, minimize waste, and streamline processes.

- Customer Confidence: Certification signals to customers, partners, and regulators that you prioritize quality, safety, and reliability.

Key Requirements of ISO 13485 Certification

Understanding the key requirements of ISO 13485 helps you build a compliant, reliable, and audit-ready quality management system tailored for medical-device operations.

- Leadership Commitment – Top management must define quality policy and ensure its integration with business goals.

- Resource Management – Adequate infrastructure, trained staff, and controlled environments are essential.

- Product Realization – Processes for design, production, and servicing need to be planned, validated, and documented.

- Risk Management & Traceability – Identify, assess, and mitigate risks throughout the product lifecycle, and maintain full traceability.

- Monitoring & Improvement – Conduct internal audits, handle non-conformities, carry out management reviews, and drive continual enhancement.

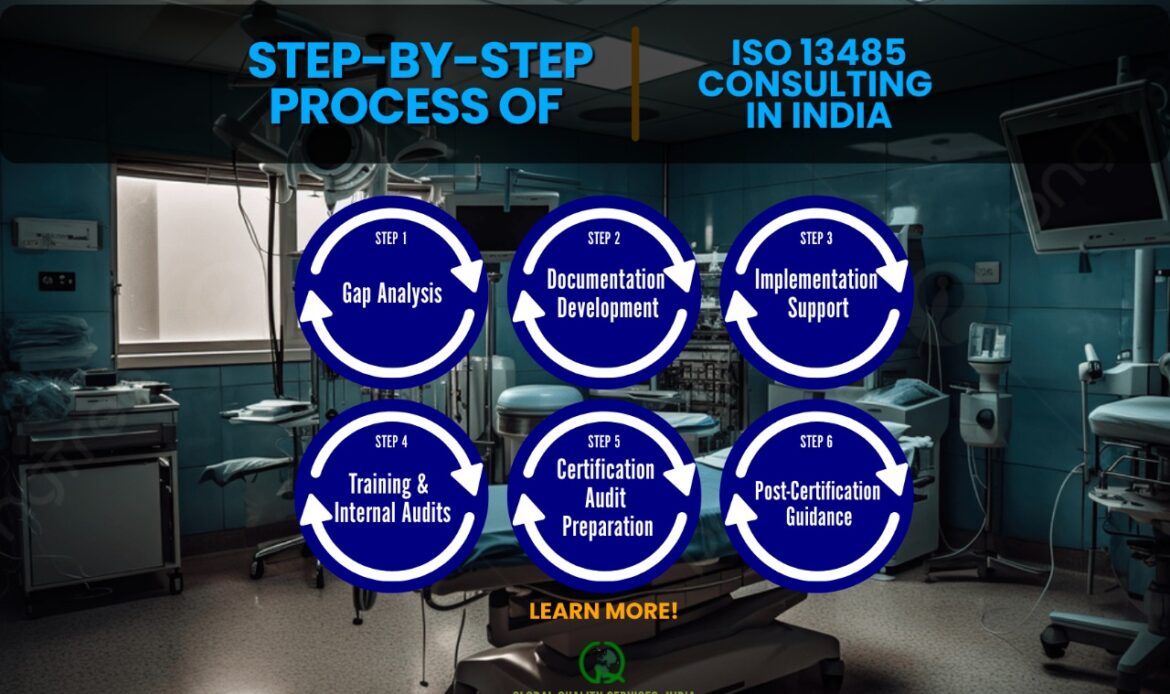

Step-by-Step Process of ISO 13485 Consulting

A structured ISO 13485 consulting process ensures smooth implementation, clear documentation, and audit readiness, helping your medical-device business achieve certification confidently and efficiently.

- Gap Analysis

We evaluate your current processes and systems against ISO 13485 requirements to identify where improvements are needed. - Documentation Development

We help you create tailored QMS documents — quality manuals, standard operating procedures (SOPs), work instructions — aligned with your operations. - Implementation Support

Our team works with you to roll out the QMS in daily operations, ensuring adoption across departments. - Training & Internal Audits

We conduct role-based training and help you run internal audits to prepare for certification. - Certification Audit Preparation

We assist during the external audit by organizing evidence, responding to auditor questions, and supporting corrective actions. - Post-Certification Guidance

After certification, we continue to support you with surveillance audits, CAPA implementation, and ongoing QMS improvement.

Benefits of Partnering with Global Quality Services

Partnering with Global Quality Services ensures expert guidance, faster certification, and a customized approach that strengthens your quality system and overall business performance.

- Customized Approach: We don’t use one-size-fits-all templates; your QMS will reflect your unique products and processes.

- Deep Expertise: Our consultants are well-versed in medical-device regulations like the FDA, EU MDR, and other global frameworks.

- Faster Turnaround: Our structured methodology accelerates certification without cutting corners.

- Cost Savings: By optimizing processes, we help reduce rework, scrap, and other quality-related costs.

- Sustainable QMS Culture: We build QMS into your organizational DNA, not just for the audit, for long-term quality excellence.

Partner with Global Quality Services to simplify your ISO 20000 certification journey and strengthen your IT service performance. Our experts guide you at every step for assured success. Contact us today.

Frequently Asked Questions

- How long does ISO 13485 certification typically take?

ISO 13485 certification usually takes 3 to 9 months, depending on your documentation readiness, internal team involvement, process maturity, and corrective actions required. With expert consulting support, the timeline becomes structured and smoother. - Which regulatory bodies accept ISO 13485?

ISO 13485 is recognized by EU regulatory authorities, U.S. FDA (with QMS alignment), Health Canada, and several Asian and Middle-East regulators, making it one of the most widely accepted medical-device quality standards globally. - Can we combine ISO 13485 with other management standards?

Yes, ISO 13485 integrates well with ISO 9001, ISO 14971 (risk management), ISO 27001 (information security), and ISO 14001 (environment). Integrating systems improves efficiency, reduces duplication, and builds a unified compliance framework. - What happens if we have non-conformities in the certification audit?

If non-conformities arise, auditors list them in a formal report. You must implement CAPA, provide evidence of corrections, and undergo a follow-up audit to verify closure before certification is granted. - Do we need to recertify after getting ISO 13485?

Yes. ISO 13485 requires annual surveillance audits to ensure system continuity and a recertification audit every three years. Maintaining documentation, training, and internal audits is essential to keep your certification active.