R2 Downstream Vendor (DSV) audits have become a decisive compliance checkpoint for Indian e-waste recyclers and ITAD partners working with global clients. Buyers today demand full visibility beyond your facility, right up to final material recovery or disposal.

This guide offers a clear, audit-ready checklist that addresses real auditor expectations, common failure points in India, and the exact evidence required to pass R2 DSV audits without last-minute stress.

What is an R2 DSV Audit and Why Does It Matter

Understanding the R2 DSV audit helps Indian recyclers align downstream controls with global client expectations and certification requirements.

An R2 DSV audit evaluates how responsibly your downstream vendors manage materials after they leave your control. Auditors verify whether environmental safety, legal compliance, data security, and ethical practices remain intact throughout the recycling chain.

For Indian recyclers, DSV audits carry a higher risk due to informal sector exposure, export scrutiny, and weak downstream documentation. A single non-compliant vendor can jeopardize your certification or client approvals.

Who Must Prepare for R2 DSV Audits

R2 DSV audits apply beyond primary recyclers, impacting every ITAD and downstream partner involved in material processing or resale.

Preparation is mandatory for:

- E-waste recyclers

- ITAD service providers

- Refurbishers and parts harvesters

- Aggregators and material traders

Downstream partners such as smelters, plastic recyclers, battery processors, and hazardous waste handlers also fall under the audit scope. Responsibility remains with the primary R2 facility.

R2 DSV Audit Scope: What Auditors Actually Check

Auditors evaluate real operational control, focusing on risk management, traceability, and downstream compliance rather than documented intent.

Auditors assess:

- Downstream legal authorizations

- Material flow transparency

- Data destruction continuity

- Export and transboundary controls

- Vendor qualification processes

Policies alone do not pass audits; auditors expect proof through records, interviews, and physical evidence.

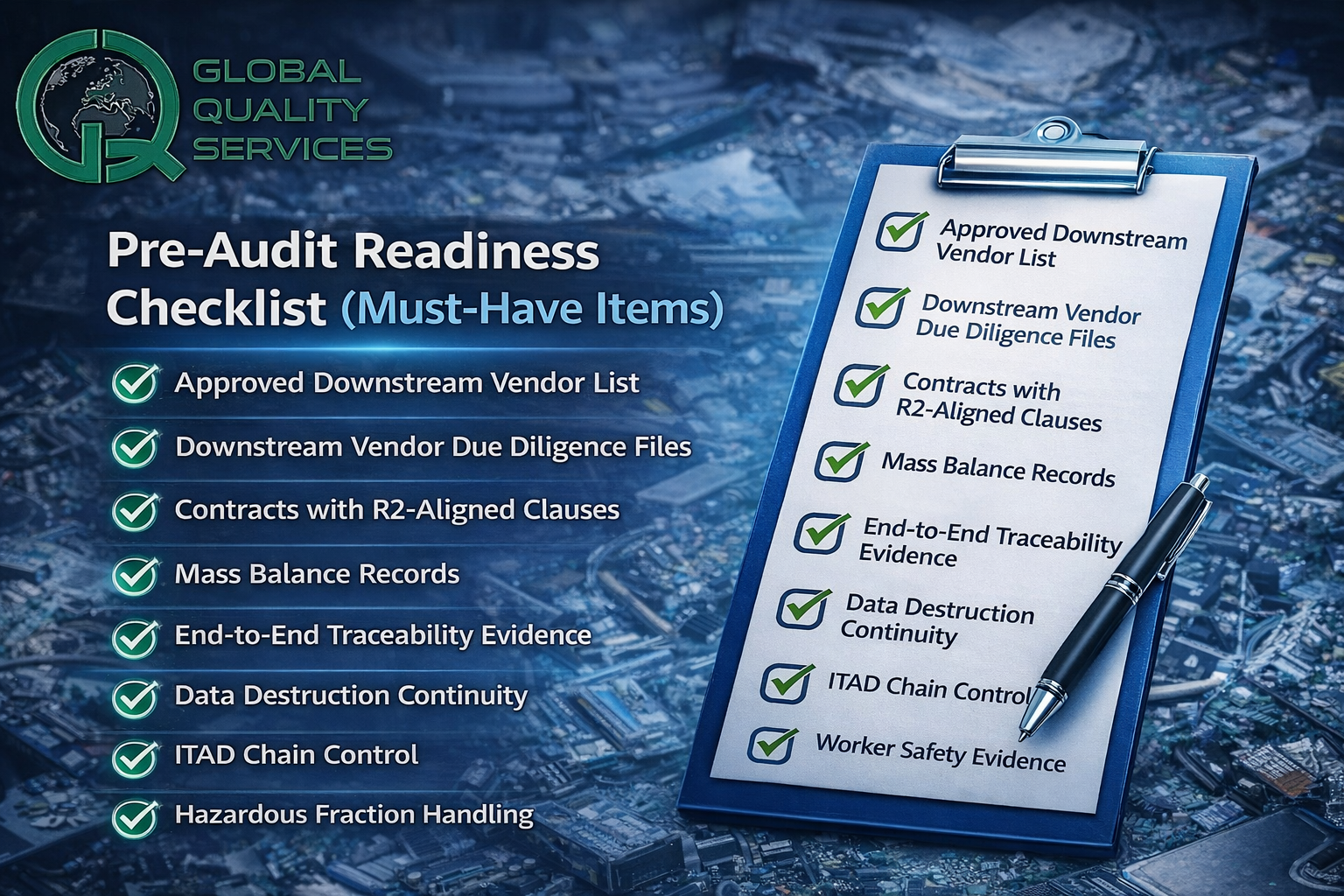

Pre-Audit Readiness Checklist (Must-Have Items)

A structured readiness checklist helps recyclers eliminate common gaps that delay approvals and trigger corrective actions during audits.

Systematic preparation reduces audit findings and demonstrates operational maturity. Disorganized documentation is the most common cause of audit failure.

1. Approved Downstream Vendor List

An accurate downstream vendor list demonstrates control over material flow and reduces compliance risks linked to unauthorized processing.

Maintain a verified list including:

- Legal name and address

- License and authorization numbers

- Material scope handled

- Permit validity dates

Avoid unapproved brokers or verbal arrangements. Auditors consider them high-risk.

2. Downstream Vendor Due Diligence Files

Vendor due diligence files provide auditors with verifiable proof that downstream partners operate legally, safely, and within R2 requirements.

Each vendor file should contain:

- SPCB/CPCB approvals

- Process flow documentation

- Site photographs or audit reports

- Environmental and safety licenses

Missing or expired approvals lead to major nonconformities.

3. Contracts with R2-Aligned Clauses

Well-drafted downstream contracts protect recyclers by formally extending R2 obligations throughout the entire recycling value chain.

Contracts must clearly prohibit illegal dumping, exports, forced labor, and data misuse. Include right-to-audit clauses and compliance accountability.

Material Flow & Traceability Preparation

Clear material tracking assures auditors that e-waste remains controlled, accountable, and compliant until final recovery or disposal. Traceability is central to R2 compliance, especially in high-risk regions like India.

5. Mass Balance Records

Mass balance documentation validates that incoming materials match outgoing fractions, eliminating concerns of leakage or informal diversion.

Maintain consistent records for:

- Incoming e-waste categories

- Processed output fractions

- Residues sent for disposal

Auditors frequently reconcile weighbridge data with invoices.

6. End-to-End Traceability Evidence

Traceability evidence proves uninterrupted custody of materials, which is critical for high-risk regions like India.

Track at least one complete batch from receipt to final treatment using logs, transport records, and final recycler confirmations.

Data Security & ITAD-Specific Requirements

For ITAD partners, auditors prioritize data protection controls to prevent information leakage across downstream handling stages. Any weakness in data handling raises immediate red flags for global clients.

7. Data Destruction Continuity

Consistent data destruction practices reassure clients that sensitive information remains secure beyond initial processing.

Maintain serial tracking, wiping or shredding logs and certificates of destruction. Downstream residual handling must also remain secure.

8. ITAD Chain Control

Strong ITAD chain controls prevent unauthorized resale and ensure refurbished devices meet legal and client-specific requirements.

Auditors verify resale eligibility criteria, export restrictions, and the prevention of informal market diversion.

Environmental, Health & Safety (EHS) Alignment

EHS compliance demonstrates responsible recycling operations and minimizes worker, environmental, and regulatory risks. EHS gaps often surface during staff interviews rather than document reviews.

9. Hazardous Fraction Handling

Proper hazardous waste handling confirms that toxic components receive compliant treatment through approved downstream facilities.

Demonstrate compliant handling of batteries, CRT glass, mercury lamps, toner waste, and chemical residues.

10. Worker Safety Evidence

Auditors validate worker safety through records, training, and interviews to confirm that policies translate into daily practice.

Ensure PPE usage, safety training logs, and emergency procedures align with actual operations.

Common R2 DSV Audit Failures in India

Understanding frequent audit failures allows recyclers to correct vulnerabilities before certification or client audits occur.

Common issues include incomplete vendor files, mass balance mismatches, informal brokers, and weak data security evidence.

Final Pre-Audit Readiness Check

A final pre-audit readiness check ensures your team, records, and downstream partners are fully aligned before the R2 DSV audit begins. Verify that all approvals are valid, traceability files are complete, mass balance data reconciles, and staff understand their roles. Confirm downstream vendor availability and keep key evidence easily accessible to avoid last-minute nonconformities.

Conclusion

R2 DSV audits demand verifiable control across the entire downstream chain. Indian e-waste recyclers and ITAD partners who invest in structured documentation, compliant vendor selection, strong traceability, and data security reduce audit risk significantly. With the right preparation approach, R2 DSV audits become a strategic advantage, strengthening certification outcomes, client trust, and long-term global partnerships. Contact us to make your journey smooth and reliable.